Exciting Changes in Leadership

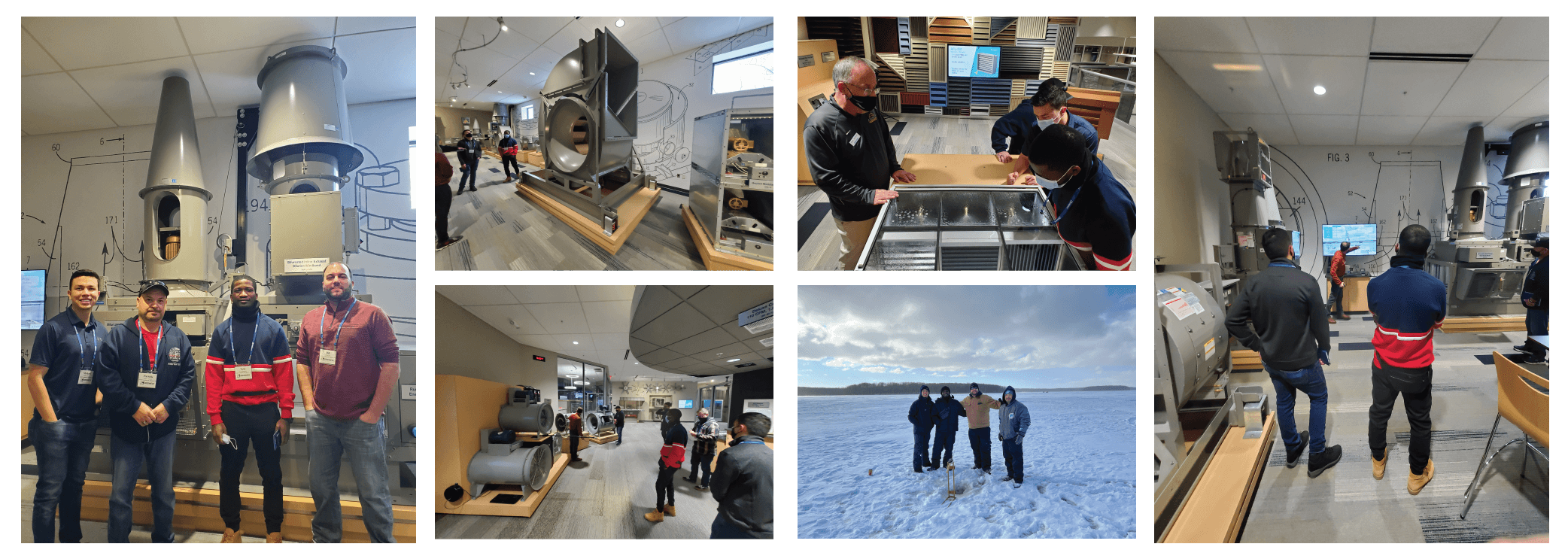

Last month, Bill Koller, Pat Fischer, Tobi Gbadebo and Michael Acosta were invited to Schofield, Wisconsin by Greenheck to tour the factory. Greenheck is an equipment manufacturer of air movement, control, and conditioning products, offering a comprehensive line of ventilation equipment including fans, dampers, louvers, kitchen ventilation systems, energy recovery, and make-up air units.

During their time there, the team learned about make-up air units, dedicated outside air (DOAS) systems, industrial and commercial fans, laboratory exhaust systems, and kitchen ventilation systems. The training included demos that compare the performance of louvers in wind-driven rain and that illusive “system effect” that fans can experience when not designed/installed properly. They were trained on the use of the online equipment selection program and how it can seamlessly integrate into Revit models. There were great discussions and videos of the process of UL listing fire dampers. They were able to see a mockup commercial kitchen with the latest in ventilation technology and take apart several types of electric motors to understand the inner workings. Additionally, there were great equipment cut-aways showing the internal, usually hidden components. But it wasn’t all work and no play for the team. They spent a part of one day ice-fishing in 15-degree Fahrenheit weather with just a little bit of wind. This is no small feat for these desert dwellers. They caught several fish which they took to a local bar/restaurant for a fish fry.

Thank you to Greenheck for the opportunity to get some hands-on learning! The GLHN team had a great time learning about how to integrate the improving technology into our designs. And while it’s fun to visit the snow, its always great to come back to sunny Arizona and our 70 degree winters!